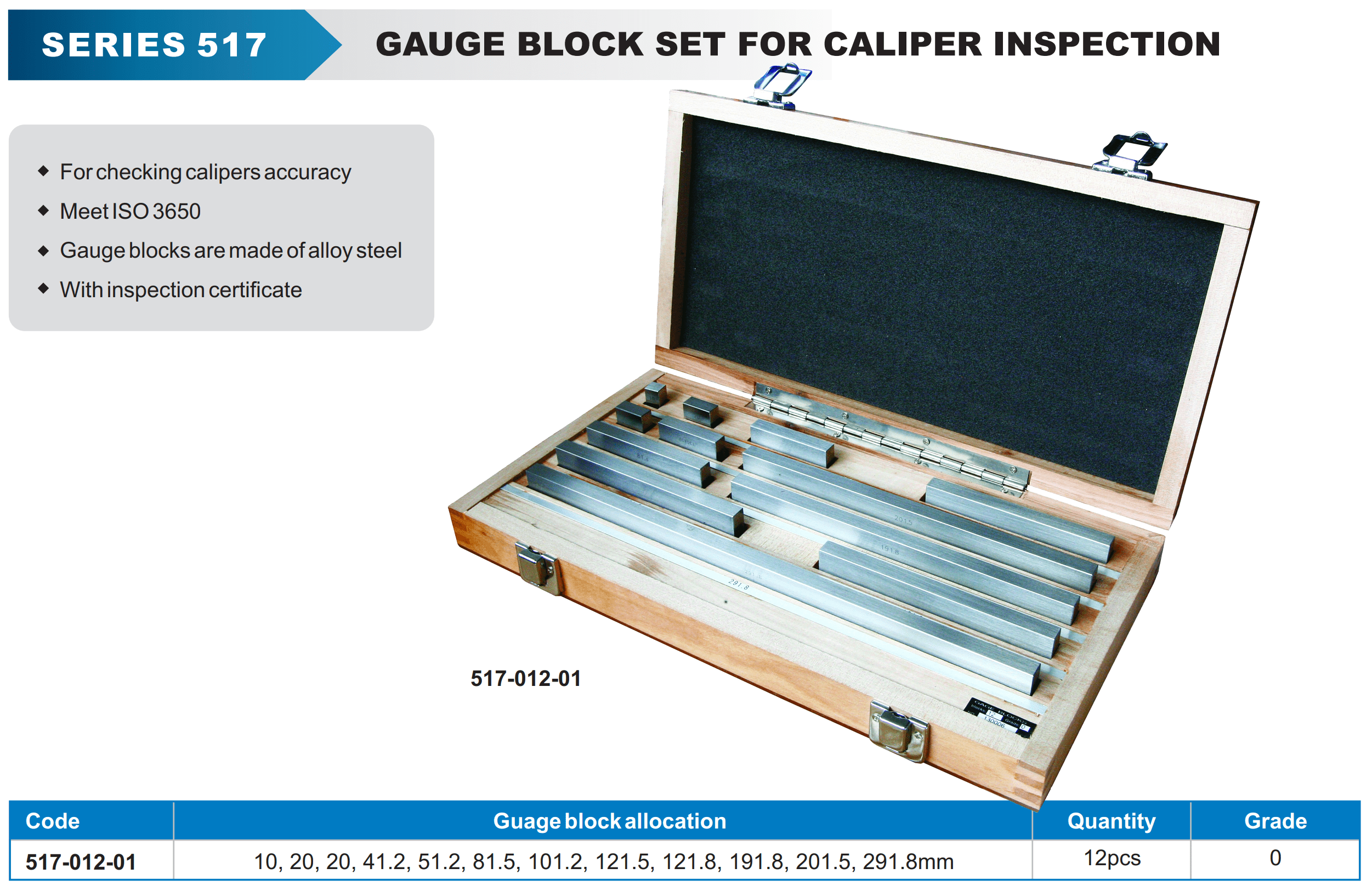

GAUGE BLOCK SET ALLOY STEEL 12PC 10-291. 8MM ISO3650 GRADE 0

GAUGE BLOCK SET ALLOY STEEL 12PC 10-291. 8MM ISO3650 GRADE 0

- Stock: 1

- Model: AC517-012-01

- Weight: 3.84kg

- Pack Dim: 170.00mm x 356.00mm x 356.00mm

- UPC: 6009515871307

Price:

R 31,573.77

Ex VAT: R 27,455.45